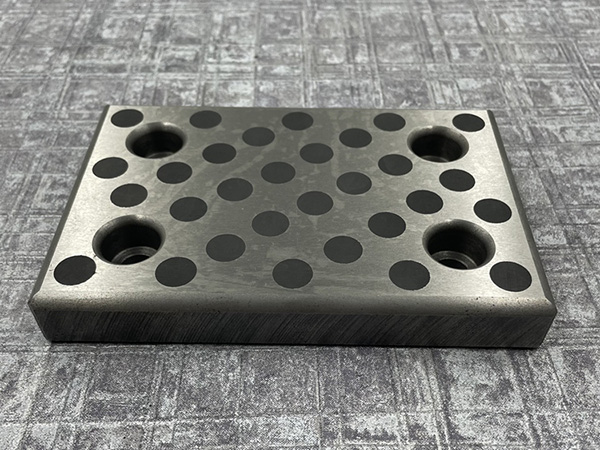

Self lubricating sliding plate

Description: The wear-resistant layer of the self-lubricating sliding plate (mainly based on actual reports) is mainly made of chromium alloy, and other alloy components such as manganese, niobium, and nickel are also added. In the metallographic arrangement, carbides

Mobile:+86 18333769655 +86 15630734447

Email:zhanghemoju@163.com

Product Description:

The wear-resistant layer of the self-lubricating sliding plate (mainly based on actual reports) is mainly made of chromium alloy, and other alloy components such as manganese, niobium, and nickel are also added. In the metallographic arrangement, carbides are dispersed in a fibrous form, and the fiber direction is straight with the surface. The micro hardness of carbides can reach above HV1700-2000, and the external hardness can reach HRc58-62.

The wear resistance of self-lubricating sliding plate alloy (mainly based on actual reports) is metallurgical bonding between the layer and the substrate. After using one-on-one self-lubricating slider equipment for tire vulcanization machine molds, active welding technology is used to uniformly weld high hardness self maintenance alloy welding wires onto the substrate. The number of composite layers ranges from one to two, resulting in multiple layers. During the composite process, due to different alloy shortening ratios, there are uniform transverse cracks on the repaired wear reducing plate, which is a significant feature of self-lubricating sliding plates.

The self-lubricating sliding plate combines the performance of copper alloy with the self-lubricating performance of solid lubricant, and can process various oil grooves and holes on the friction surface, as well as embed solid lubricant. At the same time, it can adapt to different environmental conditions, so that it does not require refueling and maintenance during use. The product is widely used for high load, intermittent or reciprocating movements, such as steam locomotive production lines and water turbines.