Process Control of Mold Parts Processing

Release time:2023-09-02 11:28:40 Author:Zhanghe mold Current clicks:68

Mold parts processing process control

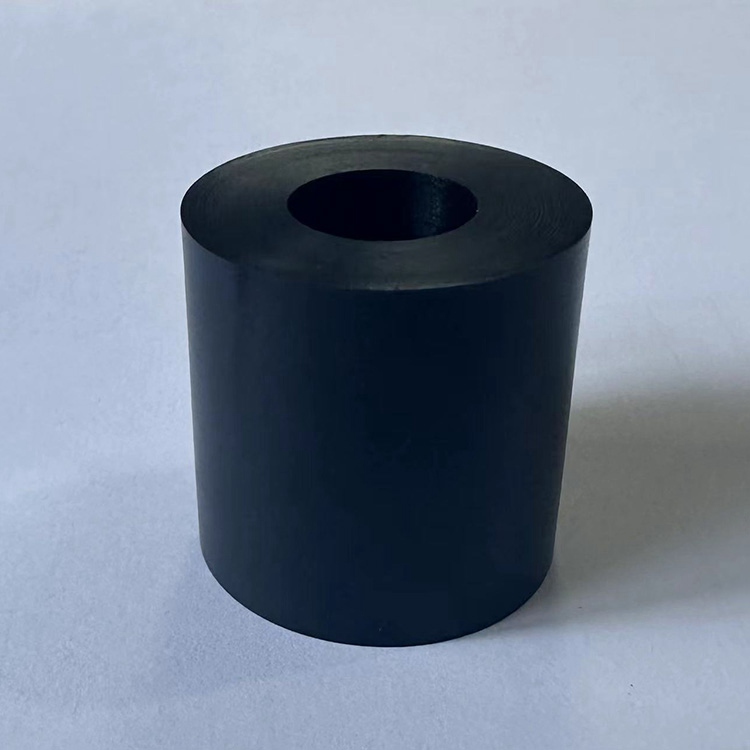

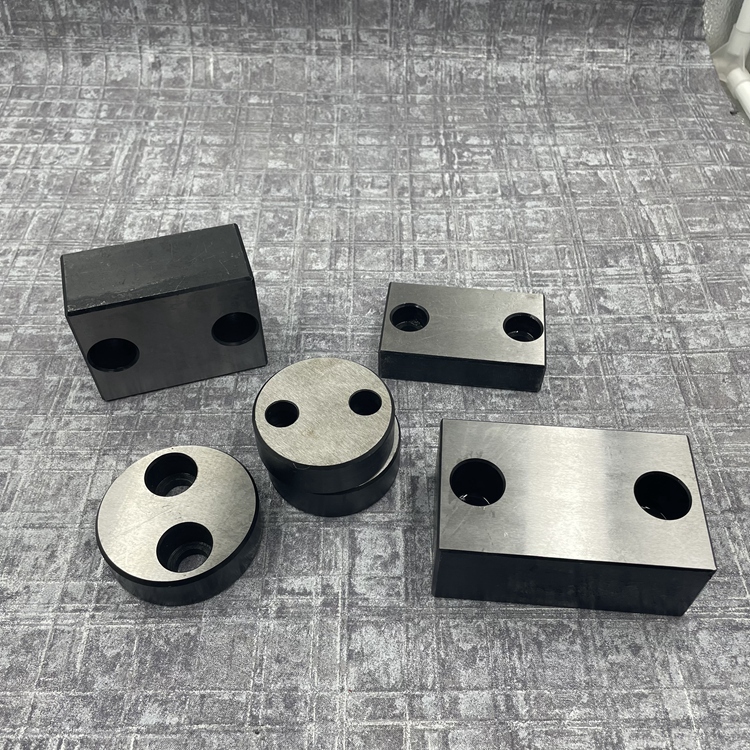

The general guiding ideology of the processing of mold parts is to carry out adaptive processing for different mold parts, different materials, different shapes and different technical requirements, and there are many selective solutions. However, through the control of the processing process, it is important to achieve good processing results and economy. According to the appearance and shape of mold parts, parts can be mainly divided into three categories: shafts, discs, plates and molded heterogeneous parts. The process of these three types of parts is generally: roughing - semi-finishing - (quenching, tempering) - grinding - electrical machining - fitter dressing - assembly processing.

1. Heat treatment of mold parts

To obtain the required heat treatment hardness of mold parts, it is necessary to control the internal stress of the heat treatment of the parts, so that the dimensional tolerances and shape and position tolerances of the parts during processing and after processing can be stable, and there are different heat treatment methods for the role of parts of different materials. The process takes into account economy, material hardenability, hardenability, overheat sensitivity and decarburization sensitivity. With the development of the mold industry in recent years, there are many types of materials used, in addition to CrWMn, Cr12, 40Cr, GCr15, Cr12MoV, 9Mn2V cemented carbide, for some working strength, harsh force of concave dies, punches, new materials powder alloy steel, such as S2, S3, V10, APS23S1, G2, G3, G4, G8 and so on. These materials have high thermal stability and good microstructure. After quenching, the workpiece generally retains internal stress, which is easy to lead to subsequent finishing or cracking in the work, and the parts should be tempered while hot after quenching to cancel the quenching stress. For workpieces with complex shapes and many internal and external angles, tempering is sometimes not enough to cancel the quenching stress, and stress relief annealing or multiple aging treatments are required before finishing to fully release the stress. Take different approaches according to different requirements. Taking Cr12 as the material of the parts as an example, after rough machining for quenching treatment, quenching only cooling methods: air cooling (the heated workpiece is placed in air to cool, this method is easy to operate, the workpiece deformation is small, but the hardness is low, and the surface is easy to oxidize. Suitable for workpieces with small size, good precision and uneven thickness), oil cooling (the workpiece is heated and placed in oil, cooled to 300 °C ~ 200 °C, and taken out in air for cooling. This method is easy to operate, the workpiece hardness is high, but the deformation is large, easy to produce workpiece deformation, suitable for workpieces with larger size and simple shape), plate clamping in air cooling (the heated workpiece is pressed between two iron plates or copper plates, cooled in air. This method is more complicated, but the workpiece deformation is small, only suitable for a special shape of the workpiece), graded quenching (the workpiece is heated and placed in a nitrate higher than the temperature of the Ms point, stay for a certain time, and after the internal and external temperature of the workpiece is basically the same, take it out and cool it in the air. This method can not only protect the hardness of the workpiece, but also reduce the deformation of the workpiece, and is widely used in workpieces with complex shape and small deformation requirements). For example, for V10, APS23 and other powder alloy steel parts, because it can withstand high temperature tempering, quenching can use the secondary hardening process, 1040 °C ~ 1080 °C quenching, and then use 490 °C ~ 520 °C high temperature tempering and multiple times, can obtain high impact toughness and stability, very suitable for molds with chipping as the main form of failure.

2. Mold parts grinding processing

There are three main types of machine tools used in grinding processing: surface grinding machines, internal and external cylindrical grinding machines, and tool forming grinding machines. When finishing grinding, it is necessary to strictly control the grinding deformation and the appearance of grinding cracks, even if it is microcracks on the surface of the workpiece, otherwise it will gradually be revealed in the subsequent work. Therefore, the amount of tool feed during grinding should be small, the cooling should be sufficient during grinding, the coolant medium should be selected as much as possible, and the parts with a processing allowance of 0.01mm should be ground at a constant temperature as much as possible. When grinding the workpiece, it is determined that the grinding wheel should be carefully selected: for the high tungsten, high vanadium, high molybdenum and high alloy conditions of the mold steel, and the characteristics of good hardness of the workpiece, PA chromium steel and GC green silicon carbide grinding wheel can be selected; When processing cemented carbide and materials with good quenching hardness, the diamond grinding wheel of organic (based on actual report) binder is preferred, and the organic (based on actual report) binder grinding wheel has good self-grinding sharpness, and the accuracy of the ground workpiece is above IT5, and the roughness can reach the requirements of Ra=0.16μm. With the application of new materials, the application of CBN cubic boron nitride grinding wheel in recent years has shown good processing results, and the finishing effect is even better than other types of grinding wheels on CNC forming mills, coordinate grinding machines, CNC internal and external cylindrical grinding machines. In the grinding process, the grinding wheel should be trimmed in time to maintain the sharpness of the grinding wheel, when the grinding wheel is passivated, it will slip, scratch, and extrude on the surface of the workpiece, causing the surface of the workpiece to be sick, microcracked or grooved, which significantly reduces the utility for future use. Most of the processing of disc and plate parts is processed by surface grinding machines, and there is a certain difficulty in processing long and thin sheet parts. Before machining, under the strong attraction of the grinding machine magnetic table, the workpiece originally had a certain bending to produce flat deformation, close to the surface of the table, after grinding, the workpiece was deformed under the action of the original stress, and the display was consistent when measuring the thickness of the plate, but due to the deformation recovery, the flatness could not meet the requirements of the mold parts, the solution was to use the contour pad iron pad under the workpiece before grinding, and the workpiece was blocked by a stop around to prevent walking, the grinding head feed should be small, and the sales volume was completed by multiple passes to complete a good reference plane. After the sales of a good reference plane is machined on one side, this reference plane can be used to adsorb on the magnetic table, and the actual effect can be based on most of the flatness of the workpiece through the grinding method as described above, such as the ideal flatness effect can not be achieved through a grinding process, the above process can be repeated again; After several such grinding, the flatness can meet the requirements, but when there are strict requirements for the thickness and size of the plate, the thickness allowance needs to be appropriately added according to the comprehensive factors such as workpiece material, shape, cutting method, heat treatment method, etc. The characteristics of shaft parts are composed of multiple rotary surfaces, and modern enterprise integrity management processing methods generally use internal and external cylindrical grinding machines to grind. In the process of processing, the use of grinding machine chuck and tail frame excellent clamping positioning workpiece or with the end of the two ejector needles to locate the workpiece, at this time the chuck and the center of the thimble connection is the center line of the grinding workpiece, if the center line beats, the processed workpiece will produce different center problems, so before processing to do a good job of chuck and excellent concentric detection and head and tail top check. If the grinding step shaft is positioned by clamping the chuck with the center thimble, the clamping part should be finely ground before this grinding, and the positioning can be centered by clamping during the first grinding. When grinding the inner hole of the book wall, consider the use of clamping process table, that is, in the turning process intentionally leave a thick wall part, to be cut off after the completion of grinding inner hole, if there is no process table then the clamping force should not be too large, otherwise it is easy to produce "inner triangle" deformation on the circumference of the workpiece, the same amount of grinding into the knife should be small, through multiple feeds to grind out the qualified requirements, in addition, the cooling during the grinding process should be fully sprayed to the ground position, so that the ground iron filings and abrasive dust particles can be smoothly discharged from the grinding area.

Other Information

-

Important processing technology for mold accessories

Production process of accessories: The actual effects of these properties are the main focus, and relying solely on the i...

-

The function of spring positioning pins

The spring positioning pin is mainly designed to cushion vibration and impact. The elastic positioning pin is designed wi...

-

The difference between spring positioning pins and positioning pins

Spring positioning pin structure principle (1): There are two springs inside the circuit breaker, namely the closing spri...

-

Application range of self-lubricating sliding plates

Application in Mechanical Design: In mechanical design, if encountering the following difficulties, priority can be given...

-

Process Control of Mold Parts Processing

The overall guiding principle for the processing of mold parts is to carry out adaptive processing for different mold par...