Introduction and product characteristics of self-lubricating slide plates

Release time:2023-09-01 11:41:27 Author:Zhanghe mold Current clicks:126

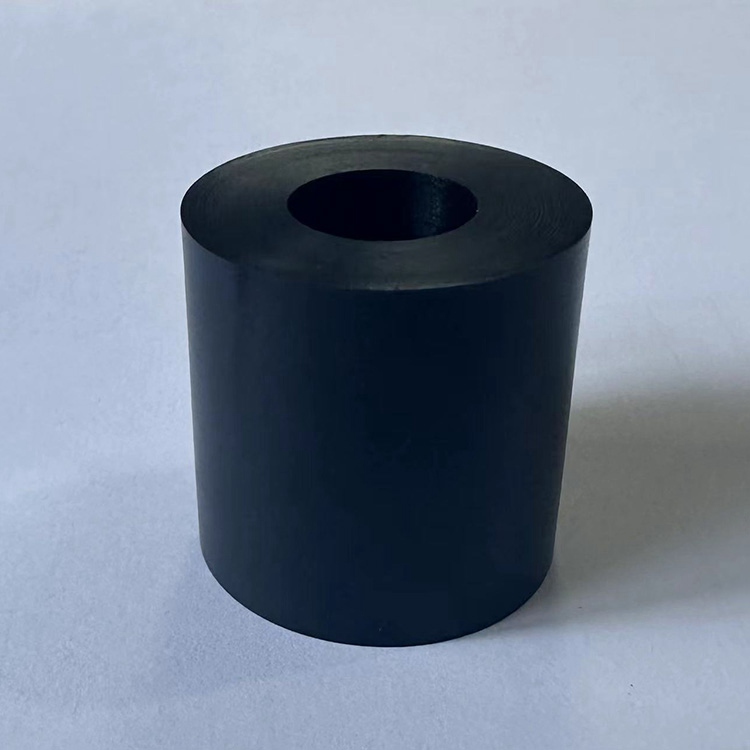

The self-lubricating slide plate is made of copper alloy as the substrate, and a solid lubricant with reliable self-lubricating performance is embedded on the metal friction surface of the substrate. The metal substrate of this bearing bears the majority of the load during the friction process. After friction, the solid lubricant in the hole or groove is transferred or reversed to the friction surface, forming a well lubricated, firmly attached, and uniformly covered solid transfer film on the friction surface, greatly reducing friction and wear. As friction progresses, embedded solid lubricants are continuously provided to the friction surface, protecting the good lubrication of the friction pair during long-term operation. This bearing breaks through the boundary of oil film lubrication in general bearings, has high bearing capacity, good performance, high temperature resistance (mainly based on actual reports) (mainly based on actual reports), low friction coefficient, low wear, no noise, good self-lubricating performance, and no wear on the shaft, There will be no jamming or other characteristics during use. Especially suitable for heavy loads, low speeds, reciprocating or oscillating situations that are difficult to lubricate and form oil films, and are not afraid of water erosion and other acid erosion and erosion. The majority of users generally reflect that embedded bearings not only save oil and energy, but also have a longer working life than ordinary sliding bearings. Jiaxing Gurun has widely used this type of product in metallurgical continuous casting machines, train supports, steel rolling equipment, mining machinery, ships, gas turbines, and other high-temperature, high load, low speed heavy load, intermittent or swinging movements

Product features:

1. It can work for a long time under oil-free lubrication conditions.

2. It is more suitable for heavy-duty and low-speed working conditions, with good performance and relatively low friction coefficient 3. Suitable for situations where oil film formation is difficult, such as reciprocating, rotating, and intermittent movements 4. It has corrosion resistance (mainly based on actual reports) (mainly based on actual reports) and chemical resistance 5. Suitable for the temperature range of -40 ℃+300 ℃ 6. Maintenance free and long service lifeProduct Material: The substrate of general embedded solid lubrication slide plates should be determined according to the operating conditions of the product itself. Commonly used materials include high-strength brass, bronze alloy, steel, cast iron, stainless steel, etc. The embedded solid lubricating materials are mainly graphite and additives. Different additives are suitable for different working conditions. According to the operating conditions of the bearing itself, the combination of different metal substrates and embedded solid lubricants can protect the product from meeting the special needs of various temperature, load, and medium operating conditions, while protecting stable and stable operation. During use, the heat of friction causes the solid lubricant to rub against the shaft, creating excellent conditions for oil and powder coexisting lubrication, which not only protects the shaft from wear but also ensures the properties of the solid lubricant for a long time

Application in Mechanical Design:Other Information

-

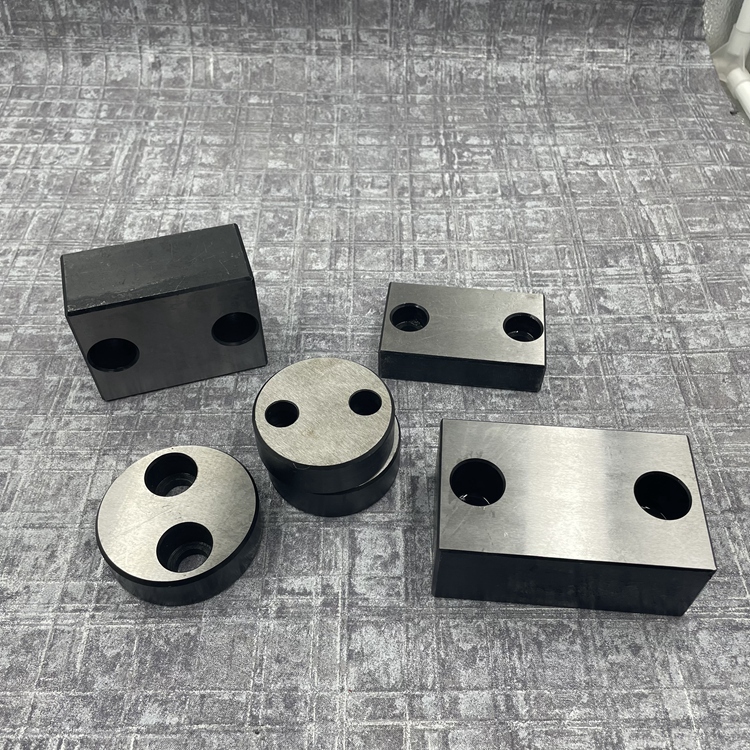

Important processing technology for mold accessories

Production process of accessories: The actual effects of these properties are the main focus, and relying solely on the i...

-

The function of spring positioning pins

The spring positioning pin is mainly designed to cushion vibration and impact. The elastic positioning pin is designed wi...

-

The difference between spring positioning pins and positioning pins

Spring positioning pin structure principle (1): There are two springs inside the circuit breaker, namely the closing spri...

-

Application range of self-lubricating sliding plates

Application in Mechanical Design: In mechanical design, if encountering the following difficulties, priority can be given...

-

Process Control of Mold Parts Processing

The overall guiding principle for the processing of mold parts is to carry out adaptive processing for different mold par...